Like many MakerBot owners, I feel compelled to help spread desktop 3D printing throughout the world. So, for the past several months, MakerBot #131 has been hard at work printing parts in 3D to make another 3D printer!

The Mendel is the second (and current) design for the RepRap project, whose goal is to create rapid-prototyping machines that can replicate themselves. As an Open Source Hardware project, everything about the Mendel’s design is available online via Subversion, from the mechanical parts to the electronics schematics, to the source code for the device and its host machine. Additionally, there is a fantastic community of very smart people who are constantly improving the design, trying new things, and helping others get their RepRaps working!

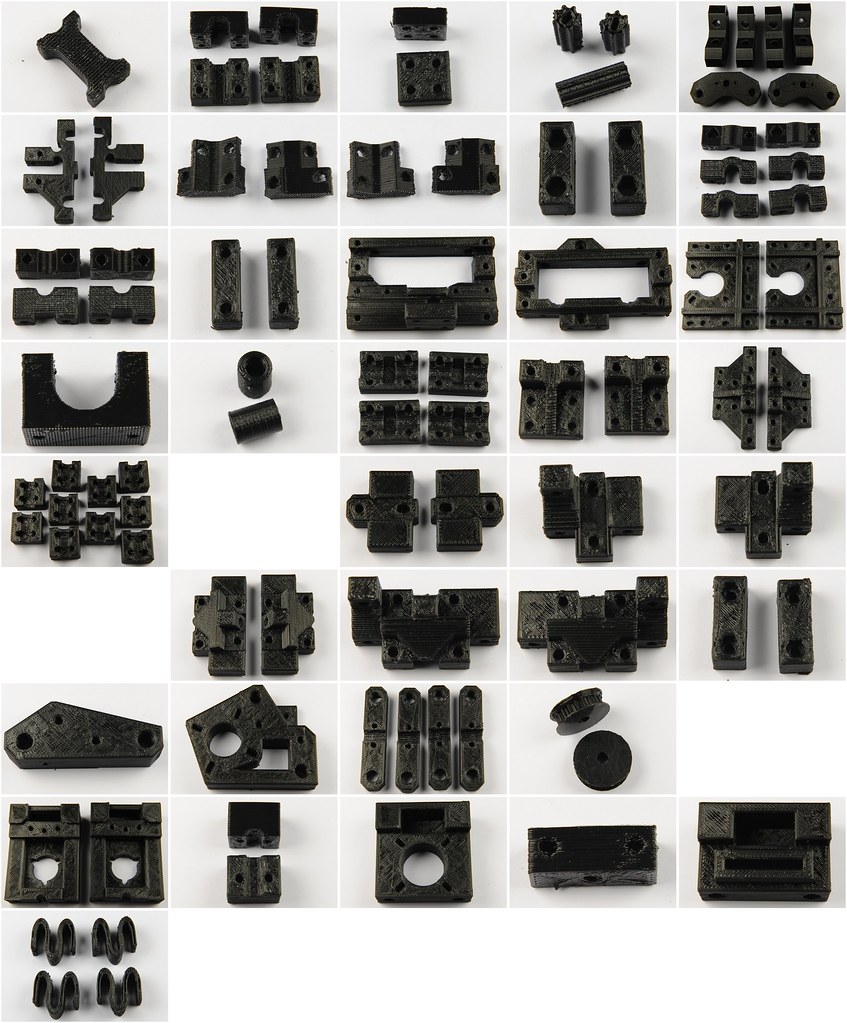

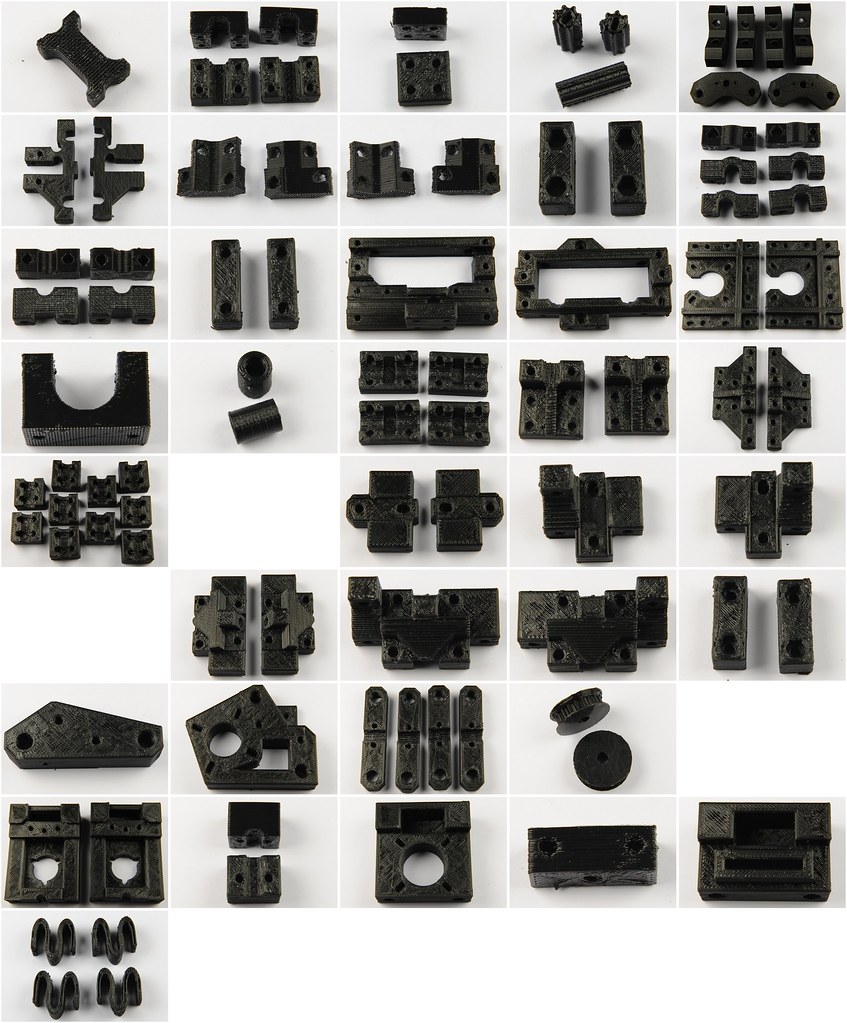

While the Mendel requires various hardware bits such as motors, electronics, nuts and bolts, etc., its structure is about 51% 3D-printed parts. This works out to about 98 individual pieces that need to be printed, and represents a huge number of printing hours.

To get started, I used a .zip file full of the 3D STL files for these parts that someone very nicely prepared and uploaded to the MakerBot Operators group. These files were from the 1.0 release of Mendel, so some of them ended up being out of date, and a few had issues that made them unprintable. Thankfully, another kind MakerBot operator uploaded a fully prepared set to Thingiverse, so I could go there for a replacement whenever I found a part that wouldn’t print.

I started printing Mendel parts almost as soon as I got MakerBot #131 working. Since I knew it was going to be a long process, I created a spreadsheet to help me track and estimate the time it would take to complete the build. I also used some silly Javascript magic to display a progress bar on my MakerBot #131 page based on this spreadsheet data:

This hack was accomplished by building my own JSONP into some cells of the spreadsheet, and loading this content as Javascript using Google Spreadsheet's plain text export capability. The spreadsheet cells were set up like this:

Here, column N47 contains the "completeness" of the Mendel as a value of 0.0 - 1.0 in terms of number of hours printed so far divided by the expected number of hours total. This data could be used on an HTML page with an "update_mendel_progress" function by loading it with a script tag:

<script src="http://spreadsheets.google.com/pub?key=t7SNwhng2GkZjKWwwSOl2VA&single=true&gid=0&range=B52:E52&output=txt"></script>

The range "B52:E52" are the cells in my spreadsheet containing the JSONP call, and the "output=txt" option returns the data as tab-separated data, which Javascript is happy to parse. The update_mendel_progress method on that page parses the number that is passed in, looks for an HTML DIV element with an id of "mendel_progress", updates it to be the appropriate width, and displays the percentage completion.

At any rate, after a lot of tweaking, many hair-raising moments, a required upgrade with the MakerBot Heated Build Platform v2.0, and hours and hours of printing, the parts were finally complete! I gave them to Matt Mets, a member of HackPittsburgh, and you can see the photos he took of the parts, above!

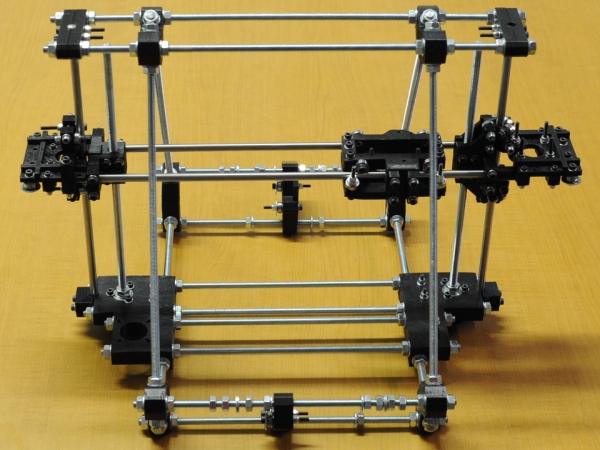

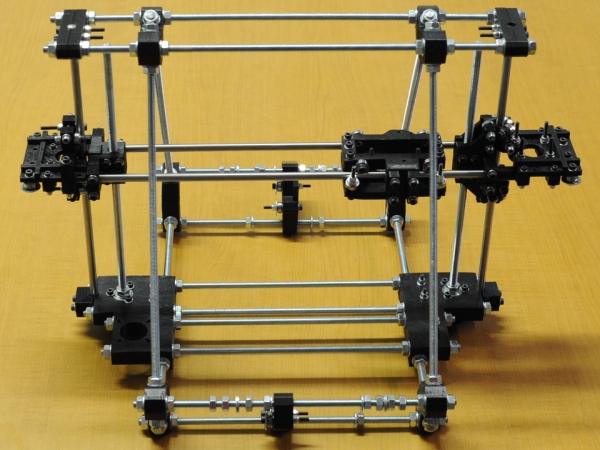

Despite some of the parts belonging to a slightly out-of-date design, Matt has been making progress on getting everything together!

You can follow Matt's progress on his blog.

I'm very happy to have finished off such a large project with MakerBot #131, and I have a lot of plans for it in the future, so be sure to watch this space for more updates!