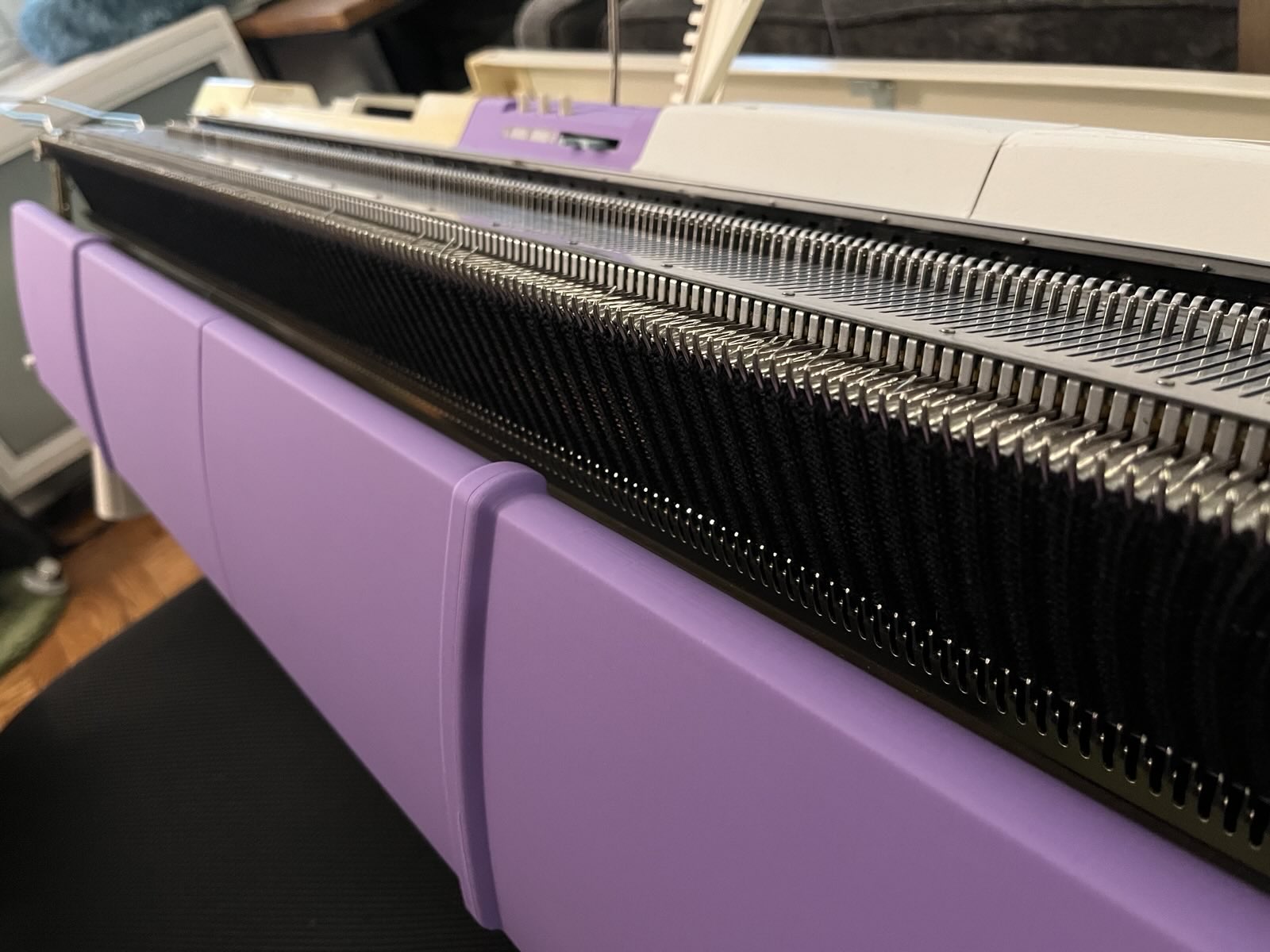

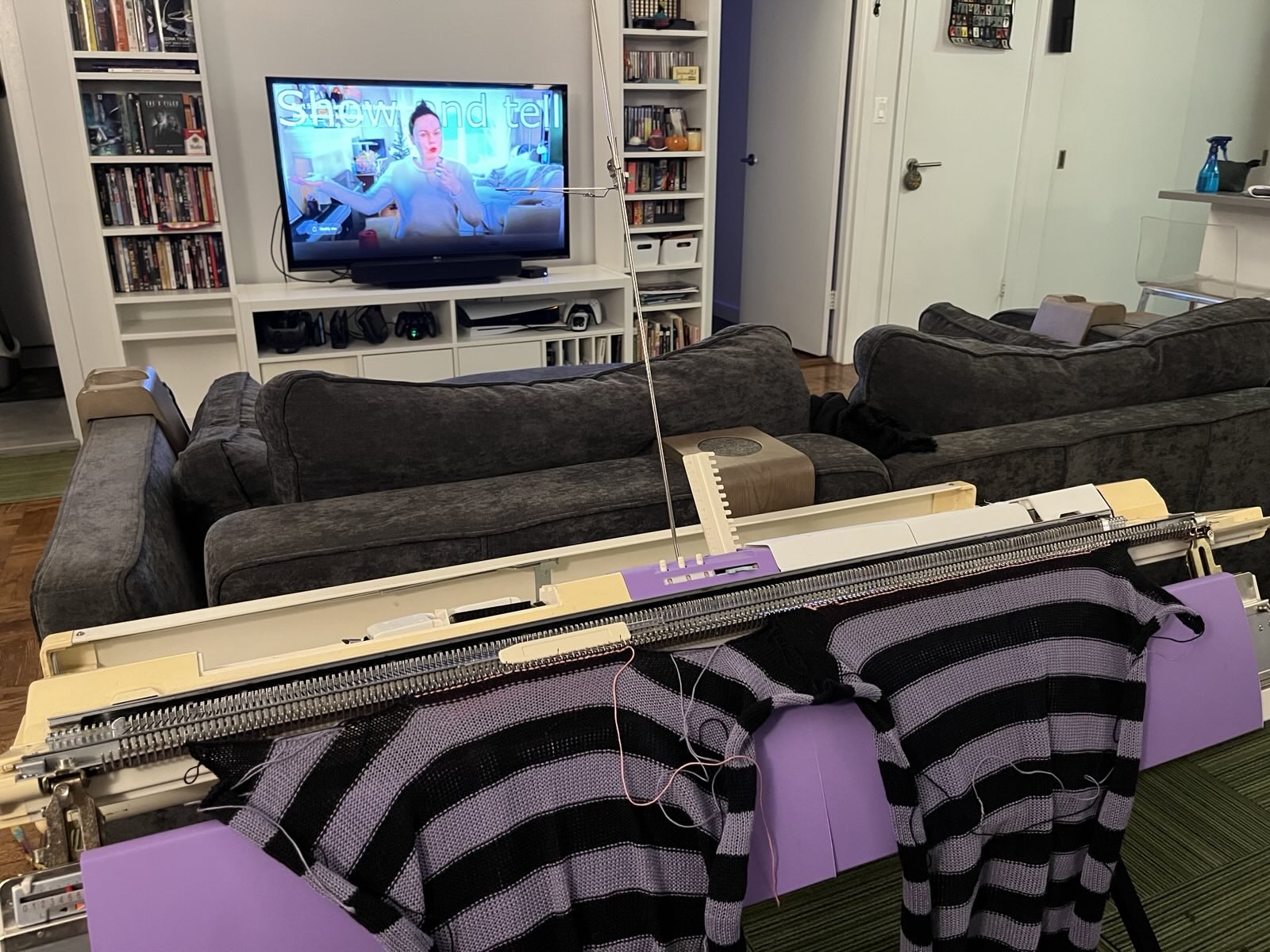

Machine knitting: neckli(n)e / show-and-tell!

This post is part of a series, as I play catch-up on KnitFactoryImpl's knitalong of a set in sleeve crew neck sweater for channel members.

After completing the front panel, only one major on-the-machine task remains for this sweater, and that's the neckline.

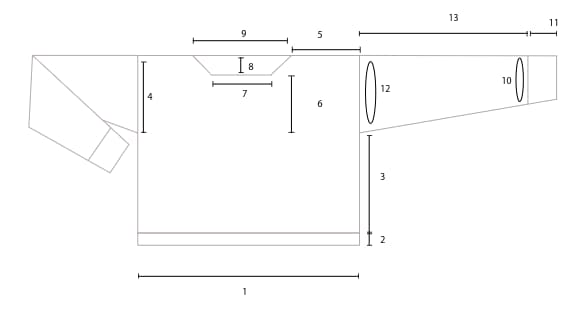

This is easy to explain conceptually: connect the front and the back by seaming them together at one shoulder, rehang all the stitches on the knitting machine, knit some rows for the collar, then cast off on waste yarn.

Still, I was dreading this for some reason, so I procrastinated on it all day and then hemmed-and-hawed as I did it.

Technically, the last bits of shoulder seams should include some purple stitches, but I found it too mind-bending to think about how to change colors while so many needles were going into hold and being wrapped. It's really just a few stitches so I don't think anyone will notice in the final sweater.

I then took a long break for food, exercise, and a shower, and only actually started hanging the neckline on the machine about 15 minutes before the live show-and-tell. 🫣

I really enjoyed the show-and-tell. It was encouraging to hear KnitFactoryImpl's own challenges and inspiring to see the final (extremely fluffy!) cardigan. I was delighted and honored that she shared my posts from this very website with some kind comments on my knitting setup and progress photos. I loved seeing photos from other participants, too! It was nice to have enough context to understand and appreciate some of the choices made in terms of stitch variety, yarn types, and (of course) colors and patterns!

I ended up waiting until after the livestream to finish hanging the stitches.

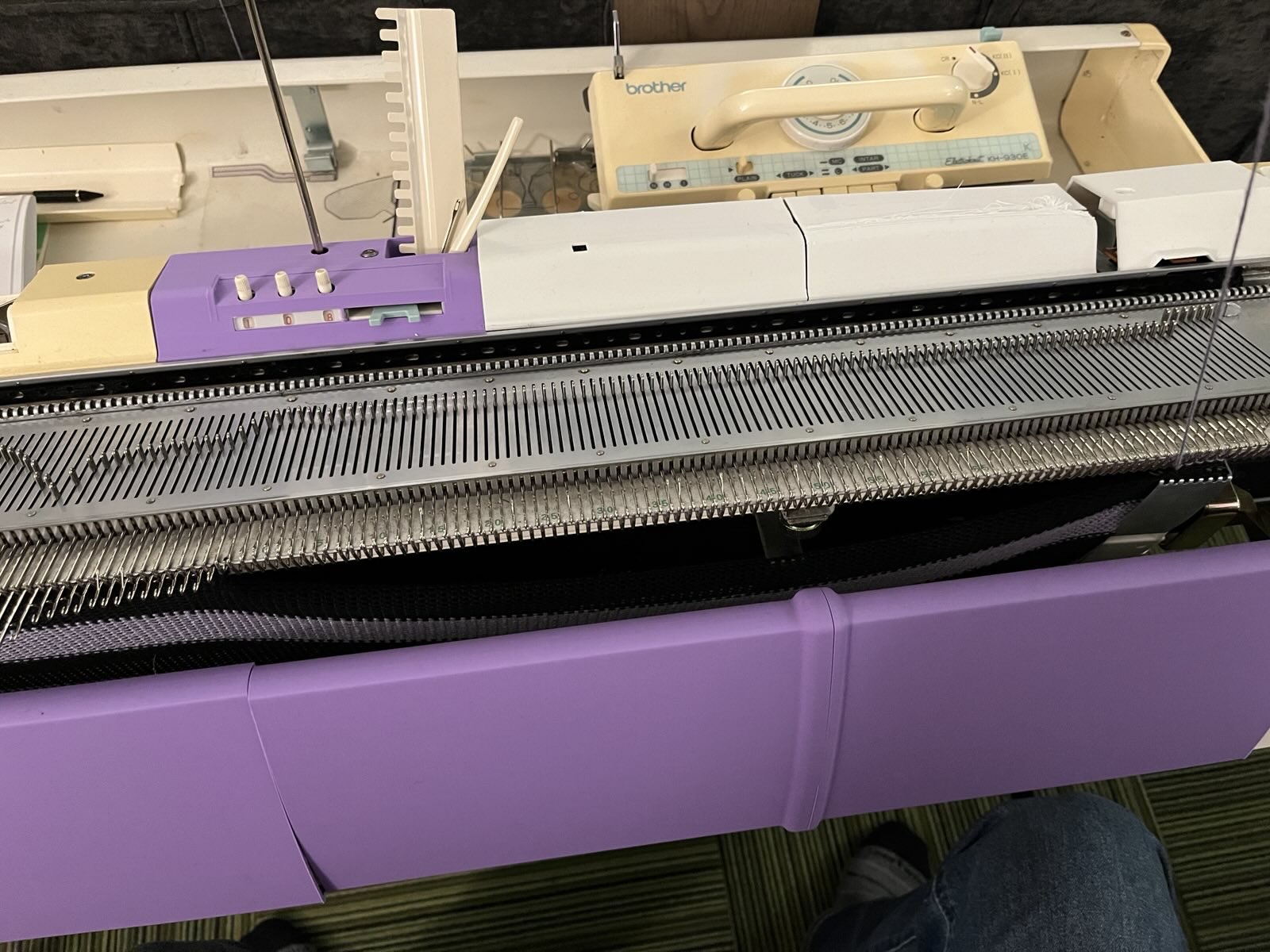

Once it was all back on the bed, following KnitFactoryImpl's advice, I:

- hung a bunch of weights.

- knit one row of normal knitting (at a slightly looser tension than the main body).

- transferred half of the stitches to the ribber for 1x1 rib.

- added more weights.

- set up the carriages to knit the rib the same as I had done the cuffs and body panel hems.

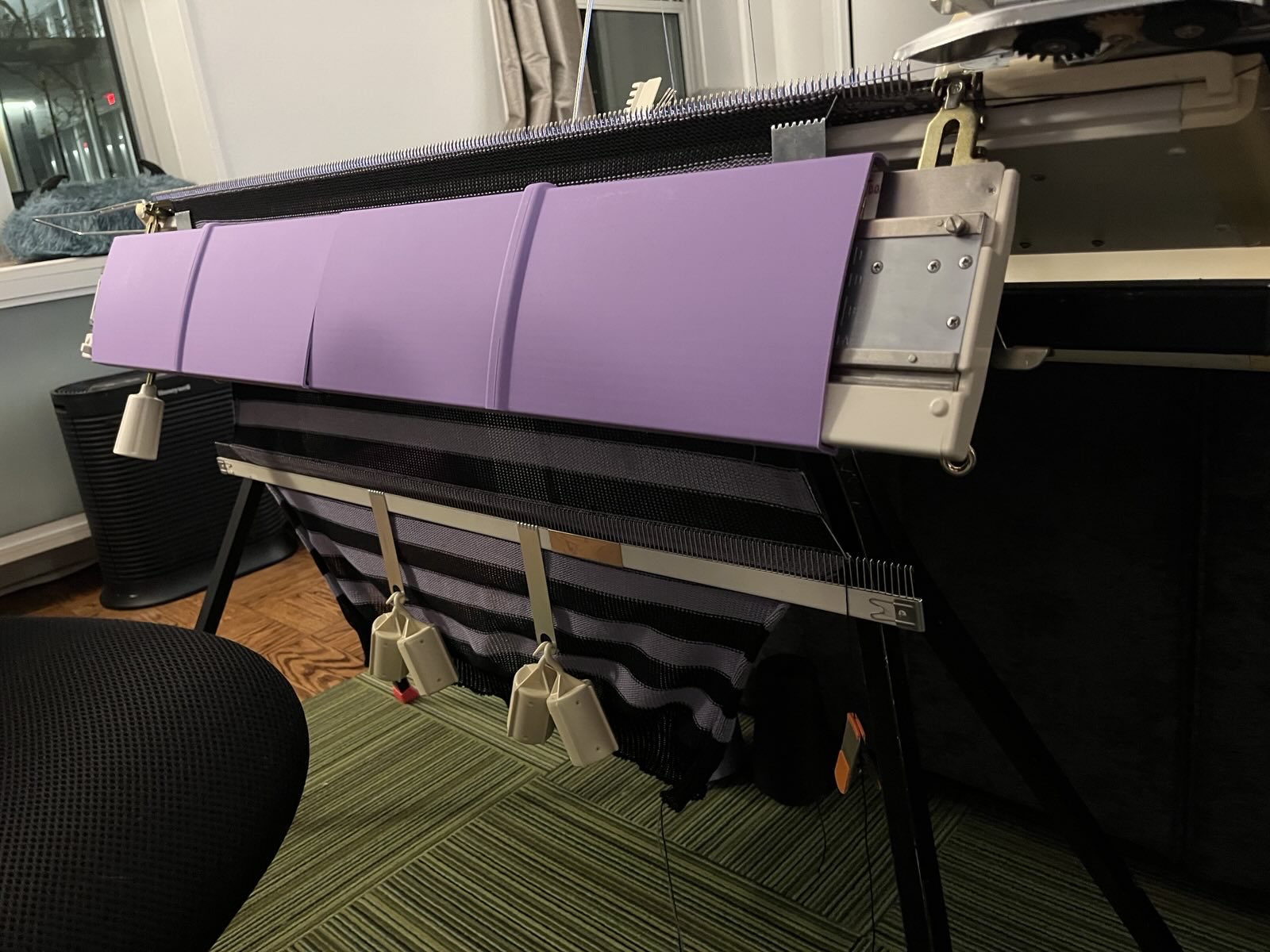

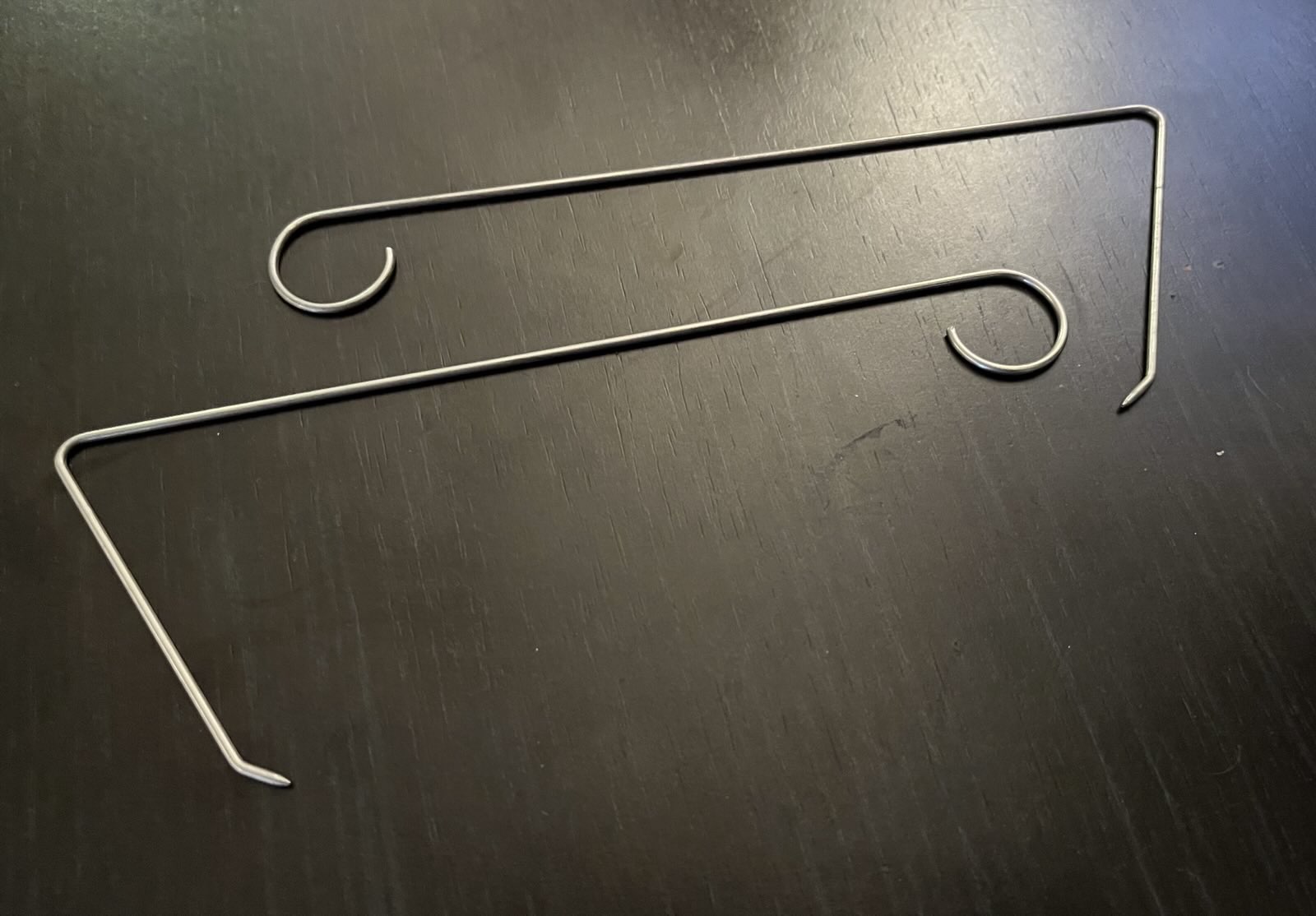

I even got to use these cool weight hangers on the edges!

After all the effort to hang the stitches, set the weights, set up the carriage, knit the one row of stockinette, remove the carriage, transfer half the stitches, set more weights, and set up the carriages again, I was feeling pretty nervous about this going awry.

So I knit 12 rows of 1x1 rib very slowly, checking each stitch after every row. This was made more challenging by the fact that my main yarn is pitch black. 😅

To my relief, those 12 rows went great! It was time to cast off onto waste yarn with circular knitting. So, I switched yarns, set the carriages for circular knitting, knit a few rows back and forth-

- and realize something was going very wrong! The tension from the weights just seemed to be not working. A bunch of stitches piled up loosely and then started dropping.

I didn't panic, but I did remove all the weights and start painstakingly removing the tangled knitting from the bed.

Most of the actual rib came off the machine fine. A few stitches have dropped but, in theory, I can fix those while sewing up to finish the seam. HOWEVER: sewing up seams is definitely one of my weaker skills, so I am not sure I trust myself to do it without making a huge mess of things.

For the sake of my future as a machine knitter, I think I will probably pull all this ribbing off and try again. It will be a time-consuming process, but it's safe to do. Importantly, it will give me a chance to figure out what bits of the knitting machine / stand / cast-on comb / hanging weights are interfering with one another, causing the stitches to bunch up after that dozen-or-so rows.

I could also stand to practice seaming and mending, a good reason to try and "rescue" this delicate collar situation.

Which will I choose? Will I let this project languish now that the knitalong is over? Stay tuned to find out!

Meanwhile, many thanks to KnitFactoryImpl for running this knitalong, for providing a super versatile free pattern generator, making extra videos to detail each piece, and pulling together and sharing photos and more from the community! Also, you know, for the tons of great instructional and inspirational machine knitting content! Go subscribe and support her channel, already!