Machine knitting: the life and death of dishcloth chattie

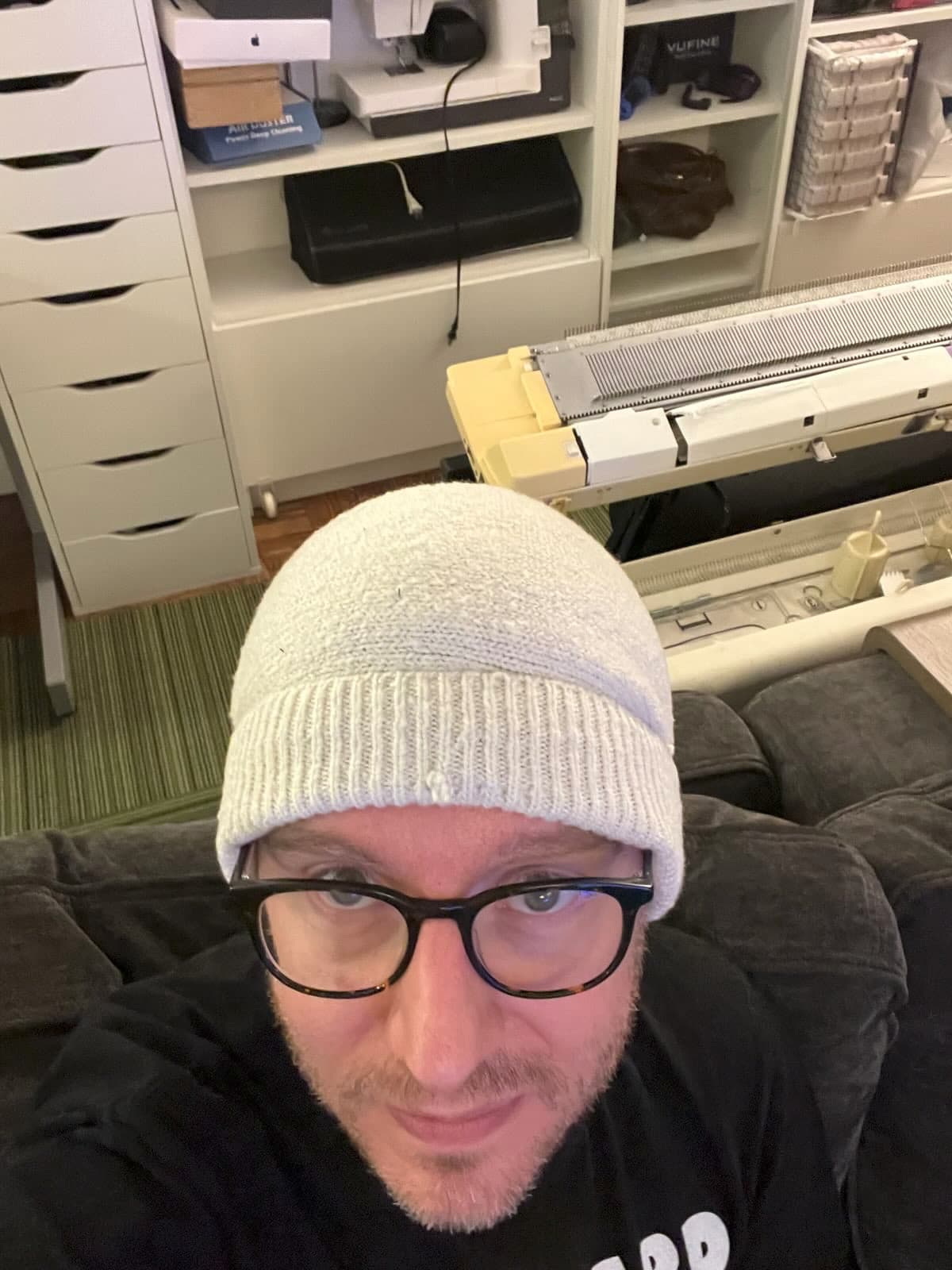

I made this test-version of a chattie hat, learned some lessons, and decided I was ready to try a "real" one for producer Amy. I have this pretty-weird cotton-blend yarn that I got from Fab Scrap some months ago. It's green, it's got slubs, some kind of elastic core maybe, I dunno. Every time I make something with it I think "this feels like a dish cloth".

The main body of the hat was made the same as my test version, with a little more care and no dropped stitches. I wanted to do as little off-machine hand-sewing as possible, so I started the rib with a fresh cast-on, then joined the finished rib to the hat body on the machine. I also hung the side edges together to seam up on the needle bed. This is where I made some mistakes!

- I sewed up the side seam inside out. 🤦♂️ I was eventually able to un-pick the seam and re-do it, but popped some stitches in the process. Re-seaming was somewhat difficult.

- Once the seam was finished, I tried it on and found I had not made enough ribbing! This material is not very stretchy and I simply did not cast on enough stitches. The end result was a TIGHT band on the hat.

The photo above is slightly misleading - this was actually the hat right off the machine, before washing and blocking. The washed hat was too tight to wear.

Oh no!

Thankfully, Home Ec NYC (the wonderful Brooklyn fiber arts workshop and studio of Hillary O'Dell) was hosting a sweater upcycling workshop, taught by Anne Warren, all about disassembling knits to reclaim yarn.

Everyone at the workshop was lovely. And it was so fun to learn that Anne is a machine knitter with a studio in Industry City, and a great newsletter full of local knitting events and resources!

Unfortunately, the chattie did not survive being de-seamed, re-seamed, and de-seamed again. We weren't able to unwind it back into usable yarn.

Thank you for your brief service, dishcloth chattie. Sometimes our purpose in life is to serve as a warning to others. Your sacrifice shall not be in vain.

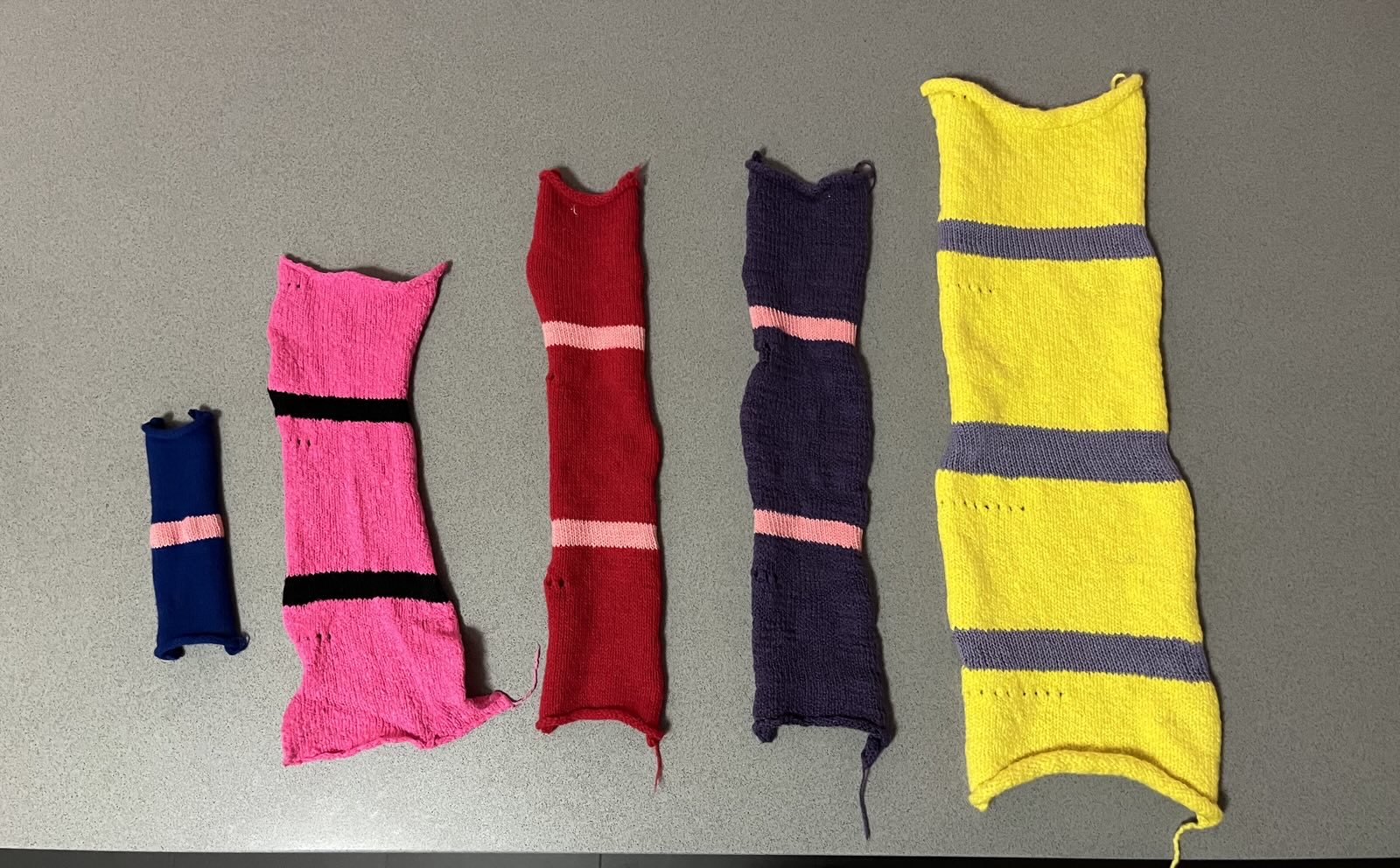

Keen eyes might have noticed a familiar blue sweater in front of me in those photos. I don't own any thrifted sweaters or other knits that I wanted to disassemble in the workshop, so I decided to embrace the circle of life. I decided to let go of my first sweater, and the crop-top life that could have been.

While I didn't quite get the clean conversion of five panels into 5 big cakes of yarn, there was a lot less waste than I expected!

Here's to this yarn becoming something new! Preferably not crop-length.